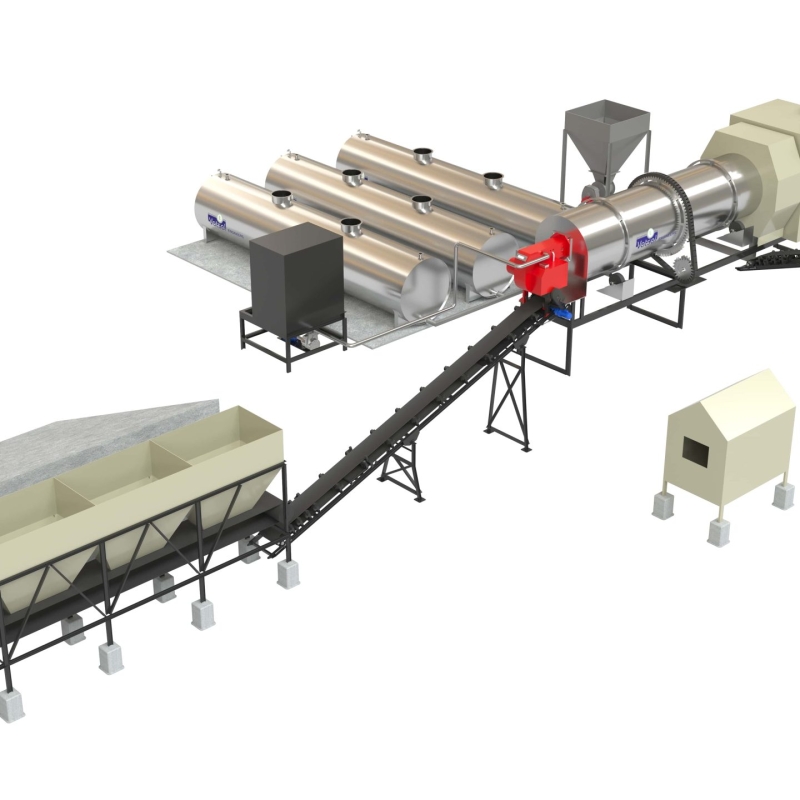

Asphalt Drum Mix Plant

VATSAL is the single source supplier of Asphalt Drum Mixing Plant. With decades of experience in the industry, we have numerous installations of various capacities to our credit. We are renowned for offering you everything that is needed to run the very heart of your business. To produce the highest quality Asphalt required as well as on-site Asphalt Drum Mix plants for the construction of large civil projects such as roads, bridges, ports, dams, runaways, buildings, tunnels, etc., VATSAL Eng. are designed to confer maximum flexibility by giving your plant the ideal combination of engineered and proven components.

VATSAL Eng. introduces VEDM Model, specially designed for the production of Asphalt at sites where quality flexibility and performance are key features to consider.

The constitution of the plant is made in welded construction of steel profiles. It’s easy to disassemble, transport and assemble again. In one week, we assemble your plant in a new site producing concrete, saving you time and money.

| Model | VEDM-45 | VEDM-50 | VEDM-60 |

|---|---|---|---|

| Capacity | 45 to 60 TPH | 60 to 90 TPH | 90 to 120 TPH |

- Overview

- Features

- Benefits

- Gallery

VATSAL ENGINEERS asphalt drum mix plant manufactured by VATSAL is known for reliability. Continuous asphalt mix plant is low on running cost, and maintenance and high on production.

VATSAL offers stationary Asphalt Drum Mix plants for sale in the capacities of 45 TPH to 120 TPH. These plants are ideal for those contractors who want to go for high volumes of asphalt production without frequently shifting from one place to another. We offer a full package to road contractors for complete peace of mind and we want them to concentrate on their core business without worrying about the equipment.

Reasons to buy Vatsal Asphalt Drum Mix Plant:

- Some of the reasons that make VATSAL Asphalt Drum Mix Plant the choice of many customers are as below Asphalt Drum Mix Plant are designed keeping the end user in mind. The quality of the machine is suitable for long life and even rough applications. A user-friendly control panel and easy maintenance make this the ideal choice for many contractors.

- The dryer drum is coated with 400-degree Celsius resistant rock wool in all our plants that are exported. High resistance of the heat-resistant material ensures that the drying drum is thermally well insulated. Heat loss is minimum in this case. In conditions where the climate is cold the plant will perform really well.

- Multi-fuel burner works with three fuel types. The burner system supplied is compatible with Diesel, LDO, FO and also CNG base. Pre-heater for furnace oil is already supplied for customers who want to use the furnace oil as a fuel.

- Flights designed for homogeneous mixing and better heating. The flights are properly designed for homogeneous mixing and they complement the burner for maximum heating with use of minimum fuel. The smoke is also less and burner is a low-noise burner.

- Bitumen storage tanks are fully stuffed with rock wool from all sides. This means that the tanks are properly insulated from all sides. This helps in preventing heat loss. The bitumen temperature is also maintained for a long time.

- Bitumen pipeline runs from the bitumen tank to the drying drum. This bitumen line is jacketed and hot oil flows in the jacketing section. This will help the tank pipeline to be hot and bitumen can flow freely.

- Mineral filler is provided with a compressor for blowing the filler material into the drum. Many asphalt drum mix plant manufacturers prefer to supply mineral filler with a blower unit to blow the filler. This blower is not as effective as a compressor. Blower is cheaper alternative to compressor and fails if the material has a bit of moisture.

- Storage silos are optional items provided with the equipment. Hot mix asphalt can be stored for some time if required. These storage silos are fully insulated from all the sides to prevent rapid heat loss.

- Control panel is PLC type in all our export plants. This is a huge value addition because we can customize PLC as per our requirements. The drum mixer that is equipped with a PLC panel is a different machine than a plant with a microprocessor panel. PLC panel is also maintenance-free compared to the microprocessor panel.

- We always believe in giving the best to customers so that they can stay ahead of their competition. Not all manufacturers and exporters of Asphalt Drum Mix Plant offer plants with PLC panels.

- Pre-testing of all the plants is done to ensure that anything that leaves our factory is ready to perform with less hassle at the site.

If you are looking for a reliable machine which is strongly built for long use, VATSAL is the answer.

- Continuous operation Four bins have individual geared motor with VFD speed control.

- High Production Capacity

- Easy to Maintain

- Energy-efficient

- Versatile

- Cost-effective

- Consistent Quality

- Reduced emissions Primary Multi-Cyclone Dust Collection unit is capable to collect dust from the drum unit.

- Automated Plant HMI & PLC with Scada with accurate weighing & assuring quality of wide range of product.

- Reduced Downtime